Quality Assurance

1. Thorough quality assurance system

Tadapla 's quality assurance is based on a management system that is based on "systems," "DX," and "track record."

-

structure

Quality control in clean rooms and clean booths

Introduction of automated assembly and inspection lines (clean rooms)Applicable for various forms

APQP

・Control Plan

・FMEA

・PPAP

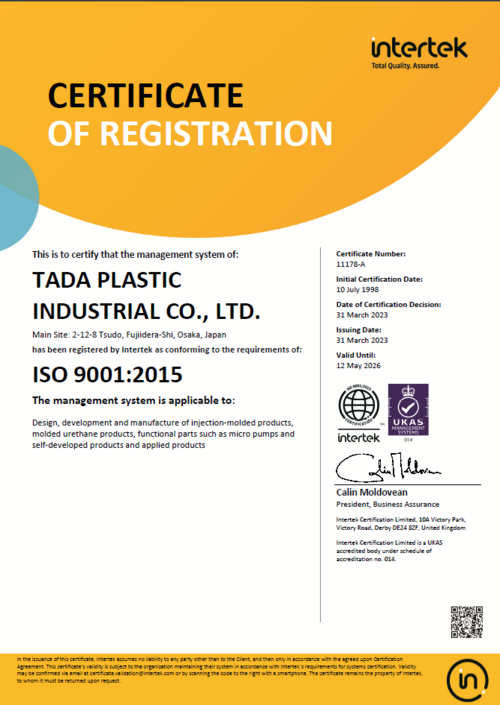

・ISO 9001 certification

We are focusing on creating systems to continue maintaining the quality of mass-produced products, such as: -

DX

We have introduced our own systems for traceability in the manufacturing process, inventory management, defect detection, and inspection systems, and are promoting the use of IT in production management.

-

Achievements

We have a proven track record of continuing to provide products to the world, from prototypes to mass-produced products and even private brand products, in a wide range of industries, including the automotive industry, medical equipment, industrial equipment, home appliances, and electronic components.

Up until now, Tadapla 's quality assurance is backed up by our track record of having passed quality audits by over 100 manufacturers.

2. Quality Assurance Equipment

We have developed a counter that can be managed in real time to prevent careless mistakes.

Quality Control

- Mixing of L/R and other set parts during the process

(Worker contamination, shooter contamination, etc.) - Contamination of defective products

(Automatically removed items mixed in, items just placed on the shelf mixed in, etc.) - Quantity Management

(Unreliable with molding machine counters and electronic balances)

Collecting input results via network

- Grasp of finished product Comparison with tablet performance

- Identify case number and compare with case in stock

- Verification of operation information Verification with tablet performance ・Downtime ・Reason for downtime

Utilization rate

3. Quality Policy/Targets

Quality Policy

Bringing together all our technologies,

Give customers satisfaction,

Provide reliable products to society.

Quality Objectives

1. Maintain the highest customer quality rating.

2. Innovative reduction of losses and process defect rates through C&A.

3. Ensuring safety and reliability, and Applicable reliably to legal requirements.